New

Product

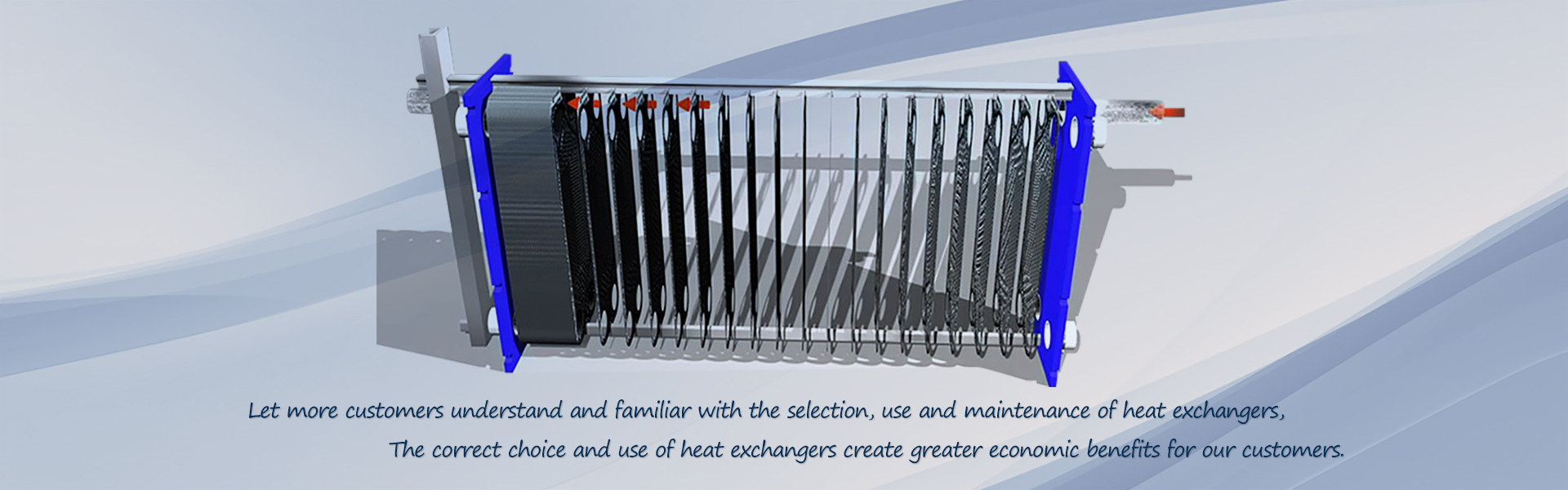

- Detachable plate heat exchanger

- Domestic plate heat exchanger seal gasket

- Semi welded plate heat exchanger

- Brazed plate heat exchanger

- Welded plate heat exchanger

- Detachable frame

- Heat recovery / heat exchange unit

- Wire winding hydraulic press

Hot news

Industry news

Manufacturing Technology of Rubber Seal Gasket for Plate Heat Exchanger

Rubber is a relatively complex polymer system, usually by the rubber polymer, curing agent, fillers, antioxidants, processing aids and thinner and other different components, including processing aids can not extend the life of rubber gasket, But to improve the gasket during the manufacturing process of mixing, extrusion and molding performance is very useful, the choice of raw materials and their ratio will determine the final properties of rubber gasket material. And the natural rubber is made from latex of the three-leaf rubber tree, the basic chemical composition is cis-isoprene; isoprene rubber is made from isoprene high cis-type synthetic rubber, because of its structure and performance and Natural rubber is similar, it is also known as the synthesis of natural rubber; styrene-butadiene rubber is made from the copolymer of butadiene and styrene, according to the production method is divided into emulsion polymerization styrene-butadiene rubber and solution polymerization styrene-butadiene rubber; Diene polymerization, compared with other general-purpose rubber, vulcanized butadiene rubber cold resistance, abrasion resistance and flexibility is particularly good, less heat under dynamic load, anti-aging performance, and easy with natural rubber, chloroprene rubber , Nitrile rubber and other use.

Under normal circumstances the plate heat exchanger gasket manufacturing process includes five process links. First, mixing kneading link, that is, according to the recipe requirements of the various raw and auxiliary materials for mixing; the second is the formation of rubber blank link, that is, through the extruder equipment will be made of plastic material; Link, the non-vulcanized rubber strip into the hot mold cavity, the mold closed for vulcanization treatment, rubber gasket in the press equipment in the molding; Fourth, after the vulcanization, is about to die vulcanized gasket static situation Placed in the oven in the final completion of the vulcanization; five is the finished product inspection, that is, part of the finished product according to process standards for finished product testing. Plate heat exchanger rubber seal gas seal principle Common rubber round ring is self-sealing principle, its seal can be maintained until the ring deformation or softening, this is because the micro-defect seal is the circular ring Bear the pressure. Plate heat exchanger rubber gasket seal is different. Plate heat exchanger to seal the operation depends mainly on the rubber gasket due to compression caused by the instantaneous sealing stress and plate heat exchanger operating pressure comparison between the sealing stress can be maintained at the operating pressure seal, and vice versa leakage occurs. The rubber gasket is different from the elasticity of the metal spring, it is a kind of sticky material. This means that the rubber in the case of long-term deformation will be the force of relaxation, that is, under constant tension or pressure seal stress will be extended with the attenuation. Higher stress relaxation is an important factor in limiting the service life of the plate heat exchanger gasket. There are two kinds of stress relaxation, one is the physical relaxation, which is due to the polymer molecules and filler particles between the rearrangement caused by the weight of the deformation with the rubber and gradually close to the balance, sealed stress and logarithm Linear relationship. The second is chemical relaxation, which is caused by the cracking of chemical bonds in the crosslinked network. Oxidation and temperature are important factors in this relaxation. The rate of stress relaxation therefore depends to a large extent on the temperature and the temperature range to which each rubber gasket applies.

Under normal circumstances the plate heat exchanger gasket manufacturing process includes five process links. First, mixing kneading link, that is, according to the recipe requirements of the various raw and auxiliary materials for mixing; the second is the formation of rubber blank link, that is, through the extruder equipment will be made of plastic material; Link, the non-vulcanized rubber strip into the hot mold cavity, the mold closed for vulcanization treatment, rubber gasket in the press equipment in the molding; Fourth, after the vulcanization, is about to die vulcanized gasket static situation Placed in the oven in the final completion of the vulcanization; five is the finished product inspection, that is, part of the finished product according to process standards for finished product testing. Plate heat exchanger rubber seal gas seal principle Common rubber round ring is self-sealing principle, its seal can be maintained until the ring deformation or softening, this is because the micro-defect seal is the circular ring Bear the pressure. Plate heat exchanger rubber gasket seal is different. Plate heat exchanger to seal the operation depends mainly on the rubber gasket due to compression caused by the instantaneous sealing stress and plate heat exchanger operating pressure comparison between the sealing stress can be maintained at the operating pressure seal, and vice versa leakage occurs. The rubber gasket is different from the elasticity of the metal spring, it is a kind of sticky material. This means that the rubber in the case of long-term deformation will be the force of relaxation, that is, under constant tension or pressure seal stress will be extended with the attenuation. Higher stress relaxation is an important factor in limiting the service life of the plate heat exchanger gasket. There are two kinds of stress relaxation, one is the physical relaxation, which is due to the polymer molecules and filler particles between the rearrangement caused by the weight of the deformation with the rubber and gradually close to the balance, sealed stress and logarithm Linear relationship. The second is chemical relaxation, which is caused by the cracking of chemical bonds in the crosslinked network. Oxidation and temperature are important factors in this relaxation. The rate of stress relaxation therefore depends to a large extent on the temperature and the temperature range to which each rubber gasket applies.

Related articles

- Congratulations on our company's quality management system, occupational health management system and environmental management system certification.

- Manufacturing Technology of Rubber Seal Gasket for Plate Heat Exchanger

- Precautions for replacement of plate heat exchanger gaskets

- Fixed method of Heat exchanger gasket

- Temporary Treatment of Aging of Plate Heat Exchanger Gasket

- Detachable plate heat exchanger which parts are formed

- work circumstances of the plate heat exchanger

- The best way to buy plate heat exchanger products

- Temperature and Pressure Requirements for Plate Heat Exchangers

蘇公網安備32028102001776

蘇公網安備32028102001776